Industry 4.0 services by TÜV Rheinland

Industry 4.0 and New Work – We support you in the digitalization of your company

Hardly any other topic shapes companies today and tomorrow more than Industry 4.0 and the digitalization of work environments. Manufacturing companies in particular are looking for a way to realize competitive advantages with technologies based on big data and the Industrial Internet of Things (IIoT). The factories of the future are intelligent, flexible, automated, efficient and sustainable. From the shop floor to the management level: big data should not only be managed, but also transformed into smart data and used with smart-data services.

The advantages of Industry 4.0 and New Work are encouraging. However, the implementation of these concepts reaches far beyond the introduction of new technologies. The human factor in the future working environment is a highly underestimated aspect. How will the transformation towards Industry 4.0 and New Work succeed?

Connected to the future with TÜV Rheinland

Industry 4.0, the digitalization of manufacturing, is not a purely technical project, but rather requires a technological, process-related and organizational approach. We support and prepare organizations and their employees to master the digital transformation within Industry 4.0.

Frequently Asked Questions (FAQ)

What is the definition of Industry 4.0?

The term “Industry 4.0” was first brought to public attention in April 2011 with the publication of the position paper “Industry 4.0: with the Internet of Things on the Way to the Fourth Industrial Revolution”. The underlying idea is to create smart factories which ensure global competitiveness through digital, highly automated and flexible processes. With solutions and technologies based on big data, machine learning, digital twins, artificial intelligence and predictive analytics, manufacturing companies are trying to achieve an optimum degree of flexibility and greater cost-effectiveness, and to create fully networked processes: a smart factory.

The result: flexible, dynamic and extremely efficient production. The machines interact and continuously exchange data with the respective software platforms. In the future, artificial intelligence will primarily control machines autonomously.

How to define New Work?

The concept of New Work means to adapt work processes and work structures in almost all industries to today's technological changes. This requires management systems and an organization that support dynamism and speed to keep up with progress. This can be achieved through integrated and flexible end-to-end processes, agility, a multidisciplinary approach and creativity. Furthermore, new skills in handling machines and technologies are required of employees. Only those companies who align their HR development accordingly will be able to exploit the full flexibility and productivity potential of Industry 4.0.

Typical traps in digitalization projects:

- Lack of integration of the human factor

- Level of complexity is too high during implementation

- Underestimated effort for integration

- Lack of maturity in terms of process and data quality

- Uncontrolled growth of applications and work formats

- Uncontrolled growth in shop floor IT

- Lack of user competence and lack of continuous development of competence

The future of digital production is close

As TÜV Rheinland, we support you in creating a suitable roadmap for the digitalization of your company. We help to make technologies securely usable and support you in developing both technical and management skills. In this way, we help you to successfully guide your employees on their way towards Industry 4.0.

For more than 20 years, TÜV Rheinland’s mission has been to support companies in making technologies safe to use. To do so, we combine our expertise in the areas of digital transformation and cybersecurity with a high level of industry know-how.

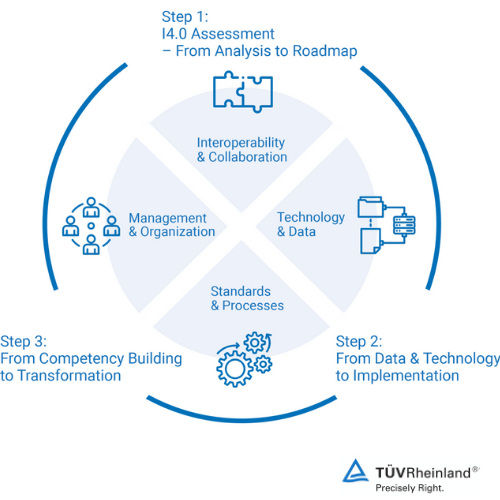

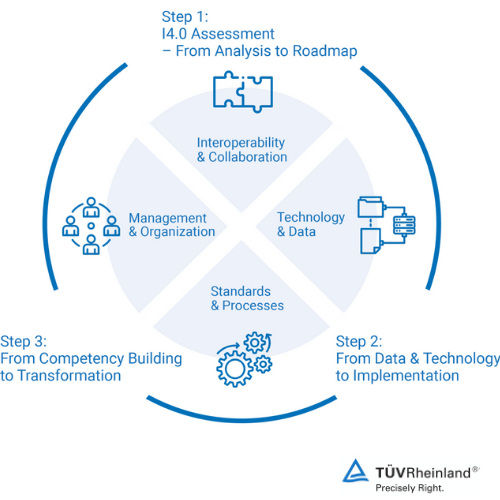

Step by step process towards Industry 4.0 with TÜV Rheinland

Consulting services for Industry 4.0 and IIoT

Benefit from our digital-transformation consulting to gain the best possible support for your IIoT and digitalization projects.

With the help of our IIoT consulting services, you can reduce costs and risks by taking advantage of our existing use cases, special laboratory environments and our implementation experience.

With our Industry 4.0 assessment, we will jointly identify your status quo and develop a roadmap towards Industry 4.0.

Smart data services.

With our Smart data services, we offer practical solutions that combine traditional methods with artificial intelligence to help our customers optimize their processes and procedures. Our services help you to identify and understand the collected data, to evaluate it appropriately and then to use it profitably.

Industry 4.0 and New Work trainings.

The changes in the world of work caused by technological development not only challenge companies to rethink and integrate these innovative technologies, but also to train and educate their employees accordingly. Here you will find our broad portfolio of training and education in the field of Industry 4.0 and emerging technologies.

Personnel certification.

With our personnel certificates concerning technologies in the field of Industry 4.0 and digitalization, you will receive qualified and independently verified proof of achieved competences. We conduct gap analyses, find the appropriate training together, including online training, and test your employees, either via online proctoring or on-site.